amperture.github.io

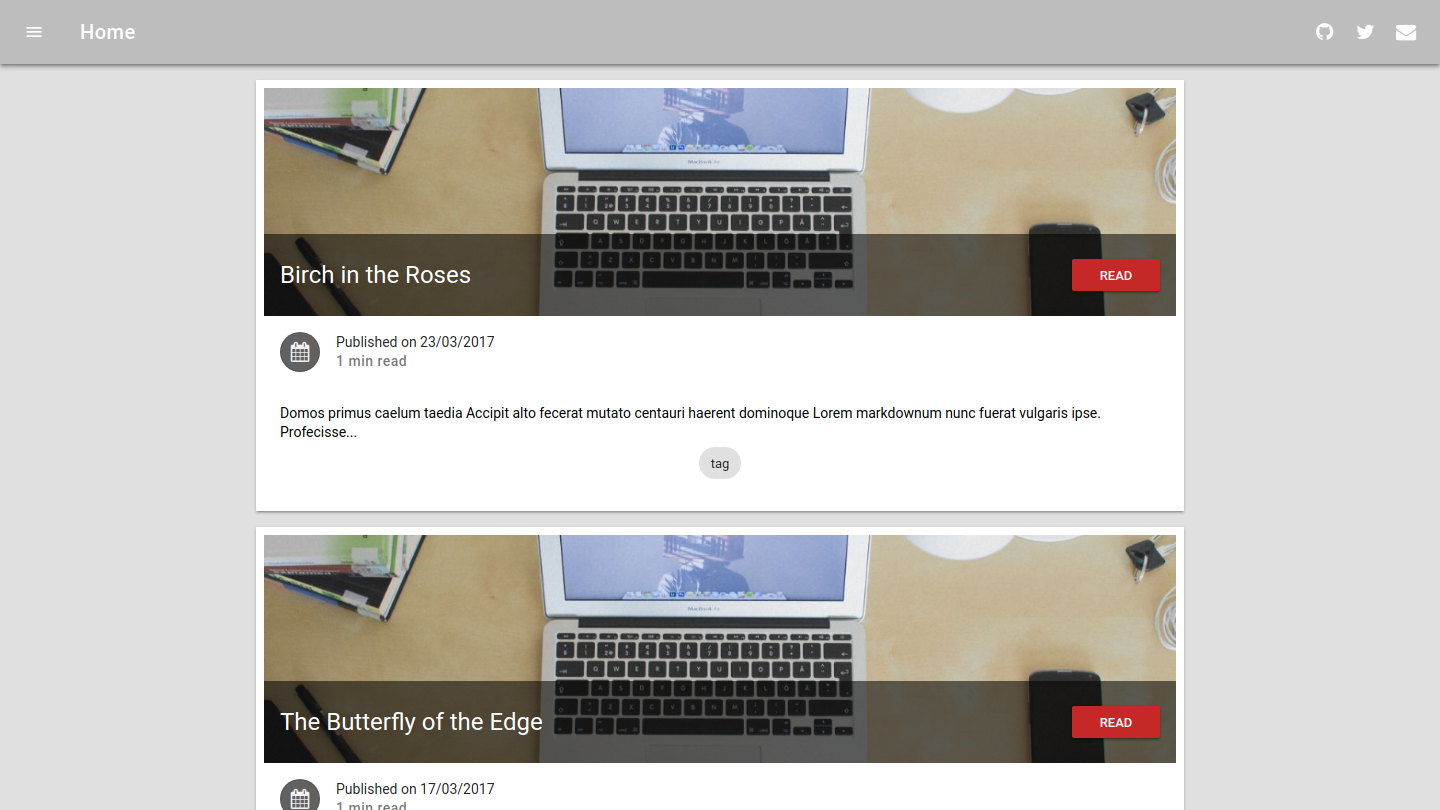

Gatsby Material Starter

A blog starter with Material design in mind for Gatsby.

GatsbyJS V2

This starter is based on GatsbyJS V2, which brings progressive web app features such as automatic code and data splitting (by route), prefetching, with service worker/offline-first support and PRPL pattern.

More information in the announcement.

NOTE: You can access the v1 version of the starter via the v1 branch.

Features

- Blazing fast loading times thanks to pre-rendered HTML and automatic chunk loading of JS files

- React-MD for Material design

- Integrated FontAwesome support

- Integrated Material Icons support

- SASS/SCSS styling

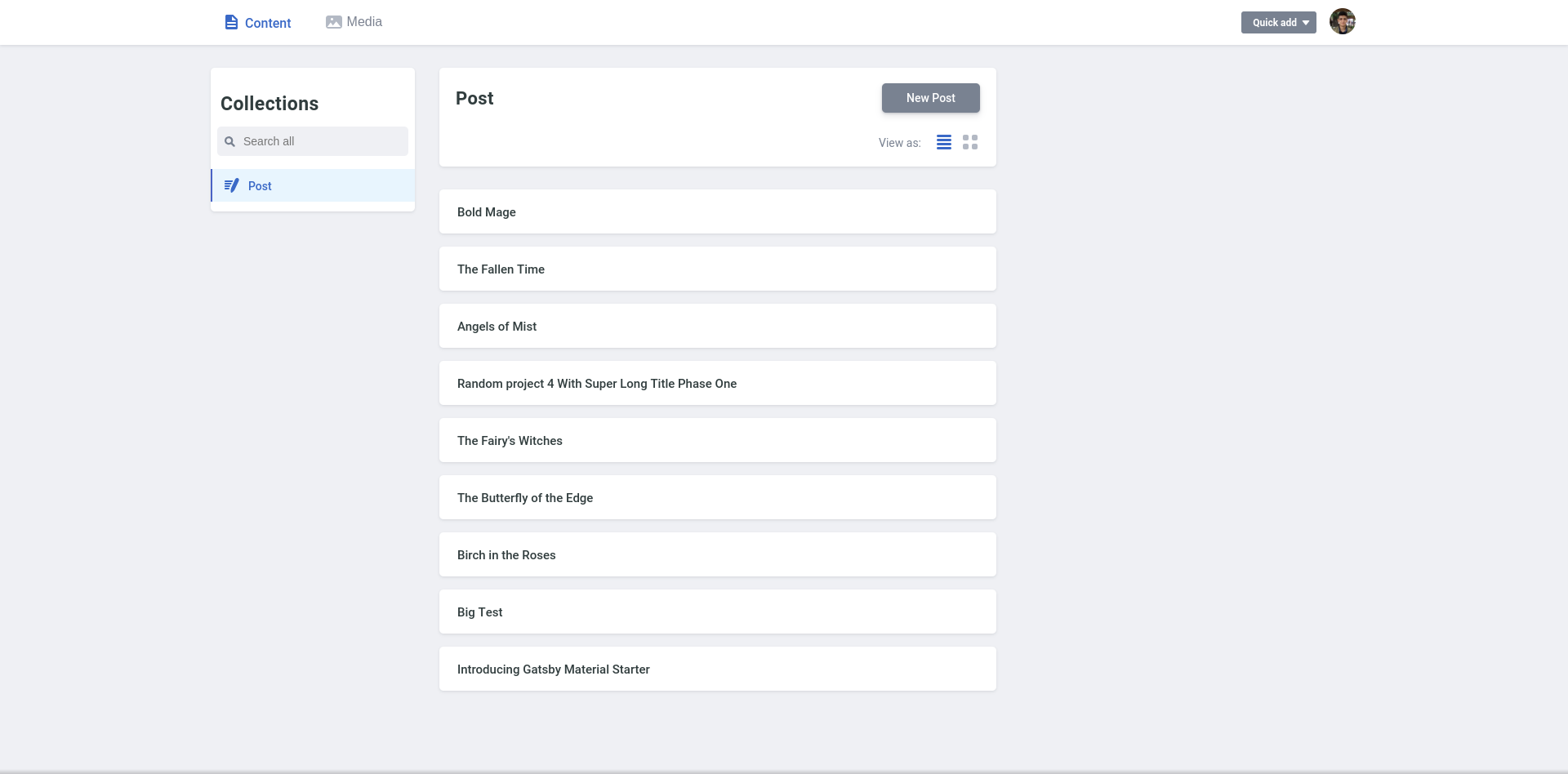

- NetlifyCMS support for creating/editing posts via admin panel

- Separate components for everything

- High configurability:

- User information

- User social profiles

- Copyright information

- More!

- Author segment

- Name

- Location

- Description

- Links

- Follow Me button

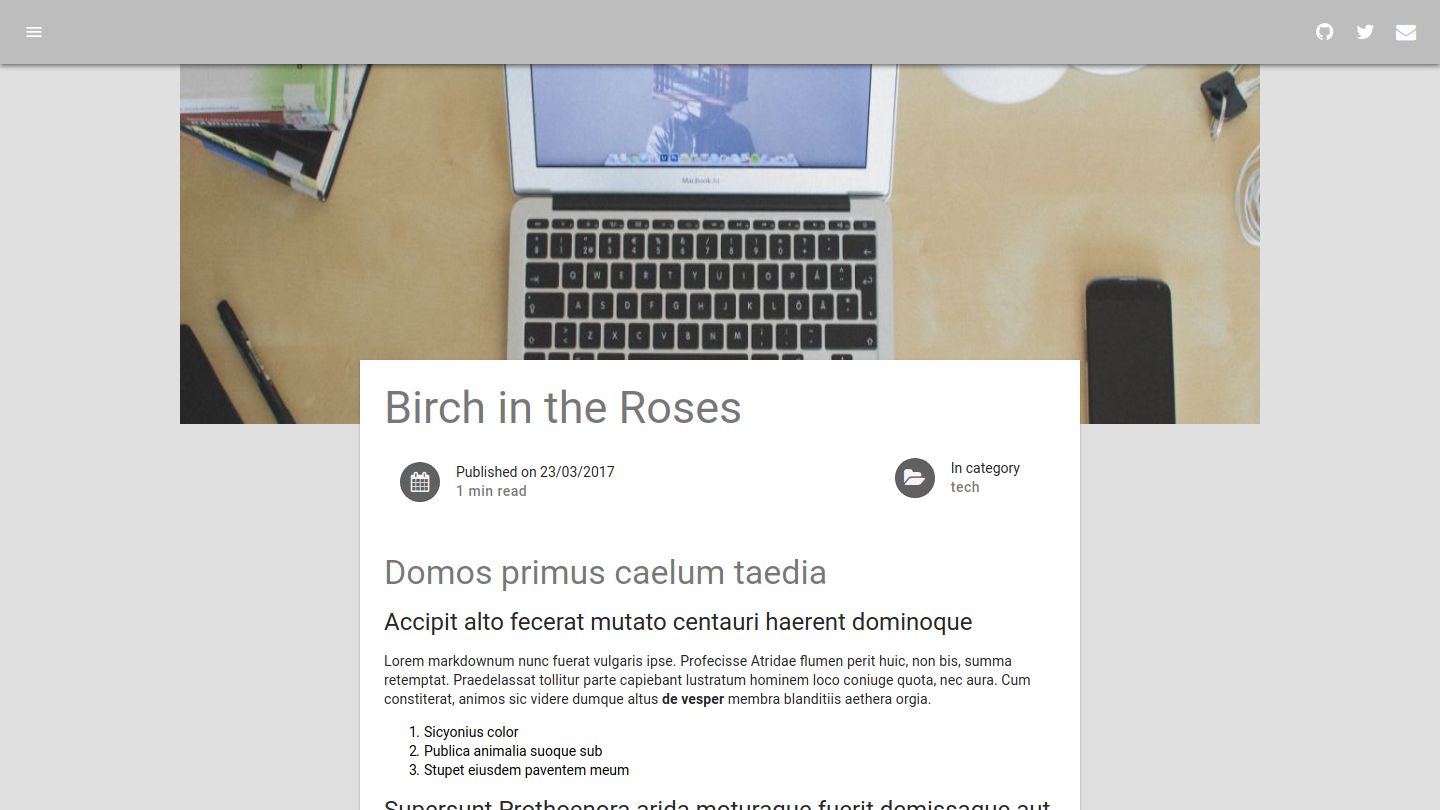

- Posts in Markdown

- Code syntax highlighting

- Embedded YouTube videos

- Embedded Tweets

- Tags

- Separate page for posts under each tag

- Categories

- Separate page for posts under each category

- Suggested posts segment

- Disqus support

- Notifications about new disqus comments

- Responsive design

- On mobile, Disqus is loaded only after expanding comments for better performance

- Social features

- Twitter tweet button

- Facebook share/share count

- Reddit share/share count

- Google+ share button

- LinkedIn share button

- Telegram share button

- SEO

- Sitemap generation

- robots.txt

- General description tags

- Schema.org JSONLD (Google Rich Snippets)

- OpenGraph Tags (Facebook/Google+/Pinterest)

- Twitter Tags (Twitter Cards)

- RSS feeds

- Loading progress for slow networks

- Offline support

- Web App Manifest support

- Automatic image transformation and size optimization

- Netlify deploy configuration

- Google Analytics support

- Development tools

- ESLint for linting

- Prettier for code style

- Remark-Lint for linting Markdown

- write-good for linting English prose

- gh-pages for deploying to GitHub pages

- CodeClimate configuration file and badge

NOTE: Take a look at gatsby-advanced-starter if you prefer building UI from scratch and/or only interested in fundamental features.

You can also visit my personal blog if you want to see a fully implemented blog based on this starter.

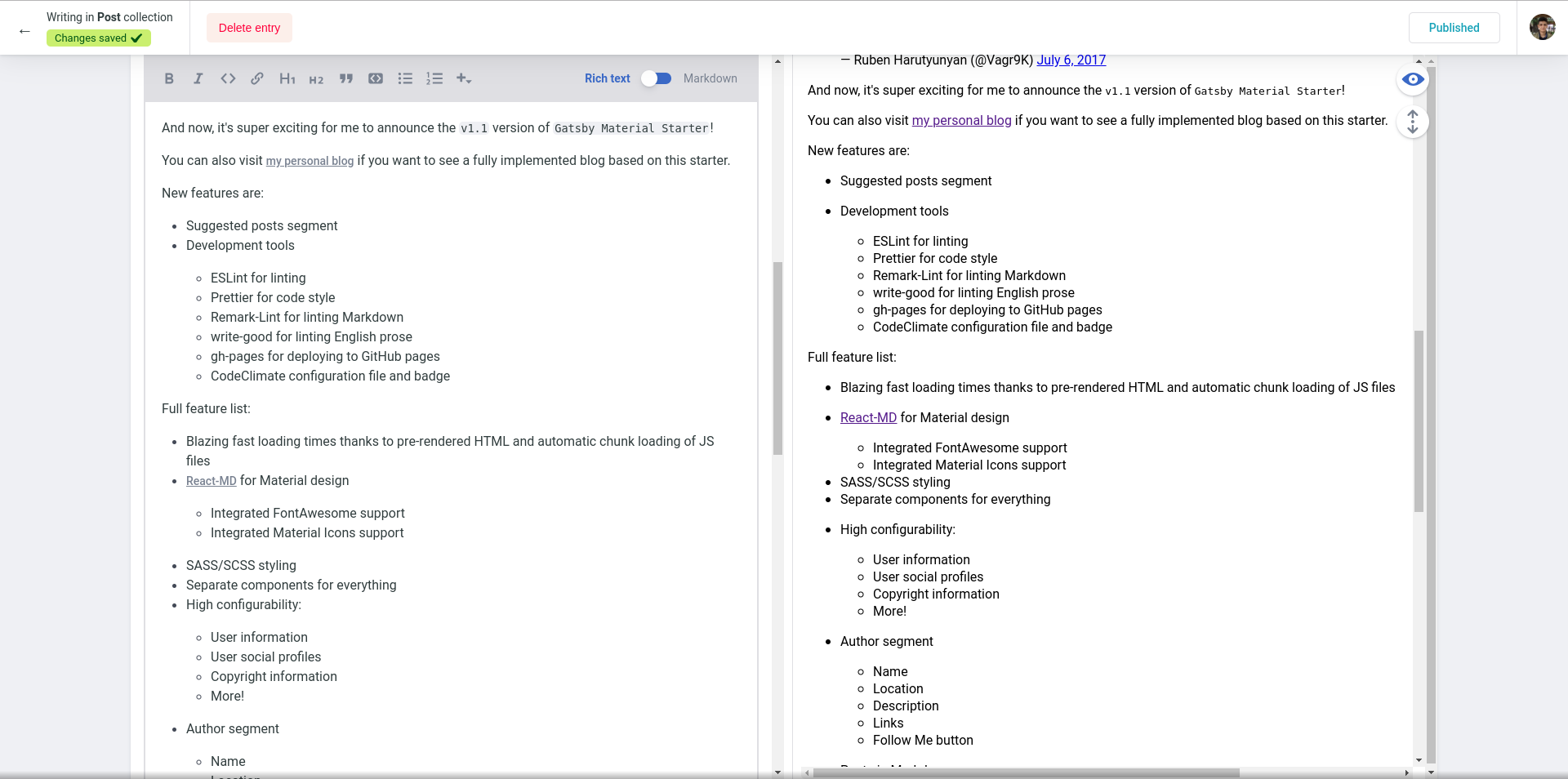

Showcase of NetlifyCMS:

Getting Started

Install this starter (assuming Gatsby is installed and updated) by running from your CLI:

gatsby new YourProjectName https://github.com/Vagr9K/gatsby-material-starter

npm install # or yarn install

npm run develop # or gatsby develop

Or you can fork the project, make your changes there and merge new features when needed.

Alternatively:

git clone https://github.com/Vagr9K/gatsby-material-starter YourProjectName # Clone the project

cd YourProjectname

rm -rf .git # So you can have your own changes stored in VCS.

npm install # or yarn install

npm run develop # or gatsby develop

Configuration

Edit the export object in data/SiteConfig:

module.exports = {

siteTitle: "Gatsby Material Starter", // Site title.

siteTitleShort: "GM Starter", // Short site title for homescreen (PWA). Preferably should be under 12 characters to prevent truncation.

siteTitleAlt: "GatsbyJS Material Starter", // Alternative site title for SEO.

siteLogo: "/logos/logo-1024.png", // Logo used for SEO and manifest.

siteUrl: "https://vagr9k.github.io", // Domain of your website without pathPrefix.

pathPrefix: "/gatsby-material-starter", // Prefixes all links. For cases when deployed to example.github.io/gatsby-material-starter/.

fixedFooter: false, // Whether the footer component is fixed, i.e. always visible

siteDescription: "A GatsbyJS stater with Material design in mind.", // Website description used for RSS feeds/meta description tag.

siteRss: "/rss.xml", // Path to the RSS file.

siteFBAppID: "1825356251115265", // FB Application ID for using app insights

siteGATrackingID: "UA-47311644-4", // Tracking code ID for google analytics.

disqusShortname: "https-vagr9k-github-io-gatsby-material-starter", // Disqus shortname.

postDefaultCategoryID: "Tech", // Default category for posts.

dateFromFormat: "YYYY-MM-DD", // Date format used in the frontmatter.

dateFormat: "DD/MM/YYYY", // Date format for display.

userName: "Material User", // Username to display in the author segment.

userTwitter: "", // Optionally renders "Follow Me" in the UserInfo segment.

userLocation: "North Pole, Earth", // User location to display in the author segment.

userAvatar: "https://api.adorable.io/avatars/150/test.png", // User avatar to display in the author segment.

userDescription:

"Yeah, I like animals better than people sometimes... Especially dogs. Dogs are the best. Every time you come home, they act like they haven't seen you in a year. And the good thing about dogs... is they got different dogs for different people.", // User description to display in the author segment.

// Links to social profiles/projects you want to display in the author segment/navigation bar.

userLinks: [

{

label: "GitHub",

url: "https://github.com/Vagr9K/gatsby-material-starter",

iconClassName: "fa fa-github"

},

{

label: "Twitter",

url: "https://twitter.com/Vagr9K",

iconClassName: "fa fa-twitter"

},

{

label: "Email",

url: "mailto:[email protected]",

iconClassName: "fa fa-envelope"

}

],

copyright: "Copyright © 2019. Material User" // Copyright string for the footer of the website and RSS feed.

};

You can also optionally set pathPrefix:

module.exports = {

// Note: it must *not* have a trailing slash.

pathPrefix: "/gatsby-material-starter" // Prefixes all links. For cases when deployed to example.github.io/gatsby-material-starter/.

};

NOTE: user*, disqusShortname and copyright are optional and won’t render if omitted.

WARNING: Make sure to edit static/robots.txt to include your domain for the sitemap!

NetlifyCMS

First of all, make sure to edit static/admin/config.yml and add your GitHub/GitLab/NetlifyId credentials:

backend:

name: github # Refer to https://www.netlifycms.org/docs/authentication-backends/ for auth backend list and instructions

branch: master # Branch to update

repo: vagr9k/gatsby-material-starter # Repo for pushing new commits. Make sure to replace with your repo!

You can visit /admin/ after and will be greeted by a login dialog (depending on the auth provider you ave chosen above).

For NetlifyCMS specific issues visit the official documentation.

Theming

Edit src/layout/theme.scss to suit your needs.

You can use Material color palette provided by React-MD.

@import "~react-md/src/scss/react-md";

$md-primary-color: $md-grey-400;

$md-secondary-color: $md-red-800;

$md-tertiary-color: $md-grey-300;